"The Little Dog Mine was located in East Gillespie. Most mines were named after numbers, like No 2, No 3, etc, but the Little Dog was called that. My father and grandfather both worked the Little Dog and both quit to get out of the mines. It was quite dangerous and you never knew how much you would work in a year. The Little Dog closed November 1968 and was torn down a number of years ago. There are some recreation parks on the site now. I remember going out to the mine a number of times since my father hauled coal to people and used the Little Dog most of the time." -- Larry Clark

Henry Schultze, a Loader at No. 8 Shaft, Killed

Tuesday Afternoon by Falling Rock

It Required Over Two Hours to

Remove the Heavy Stone off the Body, By the use of Jacks.

Between

three and four o'clock Tuesday afternoon, the news was heralded over the

city that a man had been killed in No. 8 mine, and the workmen from the

shaft could be seen wending their way homeward in every direction, and

people, anxious to know the true details of the event, made their way to

the shaft to see and hear all that could be learned of the affair.

The fatal accident occurred about 2:30 p.m. Henry

Schultze and his partner, Louis Arnoldi, had been at work in room No. 1,

entry 10 north, and last Thursday, notified Mine Boss Saner that a rock

in their room was working , and the same was examined Friday, and a

danger notice placed in a conspicuous place, for the men to keep out.

The two men did no more work until Tuesday morning, when they were

employed to take the rock down, and were cautioned to be careful and

keep from under it. The loose rock was about 12 x 20 feet long, and

about 1 ½ foot thick, of about three ton weight, being supported by one

prop, which allowed it to play. The work of getting the prop from under

it and letting it down required judgement and skill to avert danger.

They were instructed to place props on either end and then work the

center one out, but it seems that the men used their own plans, thinking

they could saw the prop off, or bore a hole in the surface and [line not

readable due to a fold in the paper] when Arnoldi [five words not

readable] to the bottom for the auger to promulgate the blasting,

cautioning Mr. . Schultze to be careful in his absence.

Just at

this time was when the fatality occurred, and from the general

surroundings, it appears that Schultze, anxious to have the work

completed, used the saw, weakening the prop until the weight of the huge

rock bore down on the slender thread left in the center, as on

examination, it showed that the prop had been sawed on all sides,

leaving about an inch of solid substance.

The horrible sight that

met the eye of Arnoldi on his return, made his blood run cold, as the

rock had fallen and beneath it his partner was encased with only an

elbow protruding. The alarm was at once given, and it required the use

of jackscrews to extricate the body from the perilous position which

served as his death-trap. The body of the poor unfortunate was crushed

almost into an unrecognizable mass, with the saw still retained in his

hand. The lifeless remains were brought to the top about 5 o'clock and

many eager observers present witnessed a horrible spectacle never to be

forgotten. The body was then conveyed to his home at the west end of

First South street.

A jury was soon summoned by Deputy Coroner

Voight and impaneled at once, then adjourned until the arrival of

Coroner Owings at 7 p.m. when they went into session at City Hall, and

the findings according to the evidence obtained, was that "deceased came

to his death by the falling of a rock, in room 1, entry 10 north, in the

Consolidated Coal Co's mine No. 8."

The deceased had worked in

the mine here about a year, being a newcomer in this country. He was 33

years age, and leaves a wife and two small children, whose means are

limited, as they were dependent solely upon his wages for support. He

was of energetic turn, quiet in manner and honorable in dealing. Our

community deplores the ghastly details that caused his untimely death ,

and offer every condolence to the wife and children that is possible. It

is one of the saddest fatalities that has come under the observation of

our people in the history of the mining interests, here.

The

funeral obsequies were conducted from Immanual's Lutheran Church

Wednesday afternoon, Rev Weisbrodt being in charge, after which the

remains were conveyed to their final resting place in the Mt. Olive

cemetery.

Contributed by Sharon Buethner, from Mt. Olive Herald 1893 Jul 29

The coal mine at White City, Consolidated Coal Company No. 15, was reputed to be one of the most modern and safest mines in the area when it closed.

"A newer mine built after the Little Dog Mine, Monterey Mine #1, is located in Brushy Mound Township northwest of Gillespie. Monterey Mine #1 is currently operating in 1997. The Behme Cemetery where I have family members buried is located on/near Monterey Coal Mine #1 land." -- Larry Clark

"Superior Coal Company Mine No. 1 was actually located in Eagerville, which is about 2-3 mles from Benld, operational until the early 1950's when it closed. I used to fish and swim in the No. 1 mine pond and fish in the Mt. Clare mine pond. They were good places to catch bluegill, bass and mostly catfish. The upper mine pond at No. 1 was cleaner since they took in the water for washing coal, and the lower pond was the recipient of the runoff from the coal washing." -- Larry Clark

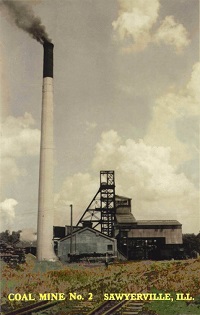

The colorized picture was taken looking more-or-less North.

Beginning of construction of the top buildings

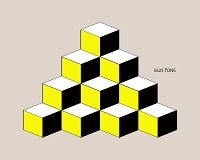

This image was painted on the side of the sand building at Superior Coal Co. Mine #2 at Sawyerville.

It is an optical illusion if you stare at it for a while. The number was the one-day

lift record for the mine. I remember the image very well because we would always

make a detour to see it when we walked to the mine reservoir to swim. The

natural drainage from the south side of Benld is into the reservoir so it also

served as the "sewage lagoon" for Benld that had a large number of outdoor

toilets at the time.

This image was painted on the side of the sand building at Superior Coal Co. Mine #2 at Sawyerville.

It is an optical illusion if you stare at it for a while. The number was the one-day

lift record for the mine. I remember the image very well because we would always

make a detour to see it when we walked to the mine reservoir to swim. The

natural drainage from the south side of Benld is into the reservoir so it also

served as the "sewage lagoon" for Benld that had a large number of outdoor

toilets at the time.

My dad's uncle was the top boss for #2 during the

40s/50s. He had the engine room all painted with different colors for each

function and all the brass polished until it sparkled. It was a showplace. I

recall my uncle holding me up so I could look through the open top of the "Dutch

doors" on the engine room to watch the big two-cylinder engine hoist the coal.

The engine turned a big drum with the mine cable wrapped around it. The cable

played out from one end and was pulled on at the other so one "cage" raised at

the same time the other lowered. A big "speedometer" (four feet in diameter)

high on the wall next to the windows looking out at the tipple showed the

location of the cages in the shaft. I also recall looking down the shaft with

the wind blowing up the shaft (the mines were pressurized with a huge fan for

ventilation purposes and the exit was up the shaft) while he kept me from making

the big fall by holding onto the waist of my pants.

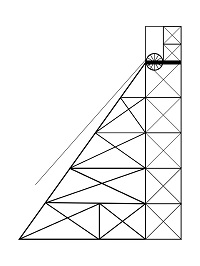

The structure over the mine pit is called a "tipple". Two elevators (cages) rose and fell

at the same time lifting out coal and delivering materials and men to and from the

mine. About 2/3 of the way up the structure was a mechanism that would "tip" the

coal cars over to empty the coal into the shakers and picking tables where the

coal was sized and slate and waste was removed by hand. The graded and cleaned

coal was then loaded into train cars and trucks for transportation. The "dock"

or "slag" was simply hauled to the south of the mine where it was spread on the

ground to create yet another one of the man made mountains that were the subject

of "supersite" cleanup many years later.

The structure over the mine pit is called a "tipple". Two elevators (cages) rose and fell

at the same time lifting out coal and delivering materials and men to and from the

mine. About 2/3 of the way up the structure was a mechanism that would "tip" the

coal cars over to empty the coal into the shakers and picking tables where the

coal was sized and slate and waste was removed by hand. The graded and cleaned

coal was then loaded into train cars and trucks for transportation. The "dock"

or "slag" was simply hauled to the south of the mine where it was spread on the

ground to create yet another one of the man made mountains that were the subject

of "supersite" cleanup many years later.

Contributed by Daryl Butcher

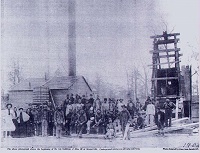

This picture of George Slaughter is thought to have been taken in Superior Mine #3 at Mount Clare.

[George Slaughter was David Richard's grandfather.]

"Superior Coal Company Mine No. 3 was located in Mount Clare, which is adjacent to Benld.

Operational until the early 1950's when it closed." -- Larry Clark

George Slaughter Tells Of Early Mining

George Slaughter, life-long resident of this community, called at this office Tuesday,

and told us that it was an anniversary for him, that he had started to work in the old

Dorsey mine east of this city on September 9th, 1882, when he was 12 years of

age. He said that school started and he didn't want to attend so he went to the

mine and secured a position. He began loading coal at the time, and worked there

for several years with a William Craig. The mine manager was a Mr. Alex Butters.

Mr. Slaughter was born near Bunker Hill in 1869, a son of the late "Grandpa"

Slaughter and his wife, the late Mrs. Chris Peeck. He made his home with an

uncle on the old William Coffee farm northwest of Gillespie and attended the

Adams school. He stated that there were only a few of his schoolmates left and

among them were Mrs. William and Mrs. Dave Thompson of Gillepie and Frank

Vannatta of Carlinville. Mr. Slaughter has been making his home with his son,

Clarence Slaughter and his wife, since the death of Mrs. Slaughter at the

Macoupin County Home in Carlinville in February. He stated that he is thinking

of going back to the home to live. He worked for the Superior Coal Company for

many years and retired in 1936 because of poor eyesight. He uses a cane to get

about town during the daytime, when he can get along without assistance.

[newspaper and date are unknown]

The picture in last week’s paper [unknown date, unknown paper] was taken

at No. 3 mine of the Superior Coal Company, many years ago, and among those

named were Dan McGill, George Slaughter, Sr., Frank McKinney, James

Wilkinson, William Granger, and Alex Thompson, and “Kidlets” Slaughter.

The picture was taken as the men were lined up to get on the cage to be

lowered into the mine for their days work. The lunch pails that can be seen

in the front row are all granite dinner pails.

The picture in last week’s paper [unknown date, unknown paper] was taken

at No. 3 mine of the Superior Coal Company, many years ago, and among those

named were Dan McGill, George Slaughter, Sr., Frank McKinney, James

Wilkinson, William Granger, and Alex Thompson, and “Kidlets” Slaughter.

The picture was taken as the men were lined up to get on the cage to be

lowered into the mine for their days work. The lunch pails that can be seen

in the front row are all granite dinner pails.

Contributed by David Richard

"I remember the coal mine at Wilsonville and went to school with kids whose parents

worked at the mine. They have been having problems with the Wilsonville mine pollution

over the years. I don't remember what the problems were/are. Operation until the

early 1950's when it closed." -- Larry Clark

To the Editor of the Post-Dispatch. In your editorial of Sept. 25 you say: In

demanding a six-hour day and a five-day week, the coal miners cannot be accused

of “gluttony.” Absolutely not! That is more than can be said for the coal

dealers and operators. The situation is this: The average cost of a ton of coal

delivered f.o.b. the mine to the operator is $1.25, 65 cents of which the coal

miner receives for wages. The coal dealers’ figures to the public show very

plainly that he is making no profit. Such figures do not deceive the coal miners

at all. If the miner receives 65 cents for mining a ton of coal, where, I ask

you, does the rest go? We know! Partly to the coal operators, but mostly to the

dealer. The operators say the miners make $10 per day. Some of them do. But how

many days in the year does he work: he works on an average of 125 days a year.

Why? Because there are too many mines and too much coal mined. He does not

average $2.50 per day. The six hour day, five days a week, will give us more

steady employment. Also, a coal mining town is the profiteers’ heaven. The

moment the miner receives 10 per cent increase in salary, the store keepers

advance their proces 30 per cent. When they are asked why their reply is always:

“Well, you got a raise.” The following is an example of some prices in Mount

Olive; Beef, Mount Olive 40 cents per pound, St. Louis 17 1/2 cents; sugar 14c,

St. Louis 11 cents. Everything else in proportion. Is it any wonder we must have

an increase in wages? Why does not the public and the Post-dispatch give heed to

the miners’ side of the case? Has not the miner the right to live the same as

other? You think that the average miner is something less than human. The

American miner is above the average in intelligence. I want to impress on you,

and in future I request that you give heed to the his side of the case. If any

of the profiteering coal dealers want to take up this matter I will make a few

more disclosures. -- A Mount Olive Coal Miner

Contributed by Larry Clark

The miners of Mines Nos. 7 and 14 of Staunton and No. 15 of Mt. Olive, all 3 properties belonging to the Consolidated Coal Co., held a mass meeting at the Labor Temple Tuesday afternoon at 2 o'clock. The men from Mt. Olive failed to get a special car over the I. T. S. so they walked to our city and it was quite an imposing parade, which wended its way through Main Street. Credit must be given that all conducted themselves as gentlemen. No vulgar or obscene language could be heard or the least disturbance noticed. The attendance at the Labor Temple was also harmonious and the issues of the day were thoroughly discussed, still we can not go into any details as the transactions concern only the miners and are kept secret. As soon as results are obtained we will make proper announcement in these columns.

Monday was observed throughout this portion of the state as the 26th anniversary of the 8-hour day victory gained by the miners. In Staunton there was no official celebration of the day, although all of the mines were idle in observance of the occasion. The 8-hour day was established on April 1, 1898*, by the Illinois Miners' Union, following a strike of 9 months' duration. By reason of the fact that the anniversary this year fell on Sunday, the celebration was deferred until Monday. At Livingston and Williamson a celebration of the anniversary was held under the auspices of the miners' locals at the 2 places. A feature of the day was a big parade from Livingston to Williamson and return, after which a program of addresses took place in front of the City Hall at Livingston. Harry Fischwick, vice-president of the Illinois Miners' organization, and Charles F. Wells of Chicago were the principal speakers. Music for the occasion was furnished by the Livingston Miners' Band.

Staunton's Fire Engine Gives Valuable Aid in Saving Mine Tipple

Monday

morning at about one o'clock workmen employed about the boiler room at No. 2

mine of the Mt. Olive and Staunton Coal Co. noticed that fire had broken out in

the lower part of the crusher room adjoining the mine tipple. The alarm was

promptly given and the the Livingston and Staunton fire department were appealed

to for assistance. In the meantime the employees played a stream of water upon

the blaze, but were unable to make much headway. The Staunton apparatus made

record run to the scene and soon had a stream of water playing on the fire with

telling effect. The local boys were assisted in their work by the members of the

Livingston Fire Department and both did excellent work.

The blaze started

under the crusher and its origin is not known. Officials of the company state

that all switches to the motors used in the crusher had been pulled at least

half an hour before the fire was discovered and believe that the fire may have

been due to spontaneous combustion, as there is always more or less dust and

moisture about the bottom of the crusher. The flames for a time appeared very

threatening and parts of the wooden supports of the tipple were burned. Due to

the efficient work of the fire departments, however, the tipple was saved and

the mine was in operation as usual Tuesday, although it was impossible to supply

crushed coal and will be impossible to do so until the new equipment, which has

been ordered, can be installed. Several large motors, parts of the crushing

machinery and a large conveyer belt constitute the largest items of loss and it

is expected that it will cost about $6,000 to repair the damage caused.

Mr. Robert Nixon, superintendent at the mine, is loud in his praise of the

excellent work done by the Staunton fire engine. The coal company's nearby pond

furnished a water supply and Staunton's powerful pumper soon had several streams

playing on the blaze, resulting in materially reducing the possible damage. The

seven hundred or more men employed at this shaft also have reason to be thankful

for the fact that Staunton has this equipment because had it not been for the

fact that this engine was instantly available, it is quite likely that the

tipple would have been seriously damaged, resulting in a several weeks'

shut-down until repair could be made. As it was the men did not lose any time as

the mine would have been idle on Monday anyway.

In our last issue the Star-Times said that there were indications that No. 2

mine of the Mt. Olive & Staunton Coal Co. might resume operations in the near

future. On Friday the resumption of operations became a certainty when notices

were posted, informing the men that an agreement had been signed and that work

would begin on Monday morning. The mine was in good condition for the resumption

of work and almost a full crew of men were on hand Monday morning. Several of

those who did not report for work are away on trips and did not learn that an

agreement had been reached in time to permit them to be on hand Monday morning.

The full force will no doubt be at work within a few days.

This is one of

the best news items it has been our privilege to publish since some time. Many

Staunton men are among those employed at No. 2 mine and the resumption of work

there will mean a great deal to our entire community. It is a rift in the

clouds, emitting a bright ray of light. President Fishwick of the Illinois

miners' organization in a statement made Saturday, said that the strike is

virtually at an end so far as Illinois is concerned. Two thirds of the men

employed in the industry in this state are said to be at work and as practically

every large company has signed up it appears only logical that the others will

follow suit soon.

The Labor Temple Theatre on Thursday and Friday evenings, May 23 and 24, will, in connection with the regular program, show a one-reel film of more than ordinary interest to the people of this community. The film is a moving picture taken underground at mine No. 15 of the Consolidated Coal Co. and shows the methods of mining coal. The film will show how coal is loaded by hand and also the new way of producing coal by means of conveyors; the old time haulage by mules and the more modern method of motor haulage will also be shown. The men who appear in the picture are Mt. Olive men regularly employed at the No. 15 mine. The Star-Times believes that this picture will be of more than ordinary interest locally and no doubt will attract a considerable crowd each evening it is shown.

Since the forepart of this week the No. 2

mine of the Mt. Olive & Staunton Coal Co., located south of Staunton, is

practically on a mechanically loaded basis, virtually all hand

loading of coal having been eliminated. Since some lime past

conveyors of the Duncan make have been in process of

installation, the new equipment being added in such a manner as

not to interfere with the operation of the mine. This

installation is now completed and a total of one hundred and

eighty-five conveyors are installed. For the time being the mine

is still being operated in two sections, but it is hoped that in

the future, as conditions in the coal industry improve, it may be

possible to again work all the men at the same time. Using the

sectional plan of operation has made it possible to avoid laying

off any of the men.

Among the new equipment recently installed is a new Arc-Wall

cutting machine which is a tremendous improvement over the

machines commonly used. This new machine is capable of

undercutting nine feet of coal and cuts a "place" in

about fifteen minutes. Operating entirely from the tracks laid

about the various working places, the machine is readily moved

and the machines will cut approximately sixteen "places"

per day. With the older type machines cutting four to five places

was a good day's work.

Sam McGurk, who recently had under consideration a position in

Pennsylvania, has decided to remain at No. 2 as superintendent,

while Ben. Chapman, the mine manager, will also remain in that

position. In order to facilitate the handling of the new

equipment Messrs. Harvey Stroud, James Hoy, Leo Safko and Norman

Chapman have been promoted to assistant mine managers. No. 2 mine

has a hoisting capacity at 5000 tons and has always been one of

the most steadily operated mines in this vicinity. The new

equipment will make for increased efficiency and should prove to

be a material aid to the sales department in landing contracts.

The Mt. Olive & Staunton Coal Co., of which Mr. Brewster is

president, is rapidly adjusting itself to the changed conditions

in the coal industry and indications are that its shaft at

Williamson will operate half time or more during the remainder of

the summer with a proportionate increase in fall, when the demand

for coal becomes greater.

It falls to the lot of a newspaper to print bad news as well as good news and unfortunately we are compelled this week to give space to an item which we would far rather not publish, namely the shutting down of the No. 7 mine of the Consolidated Coal Co. Word was received at the local offices of the company on Friday, ordering that no more coal be cut and that the men be instructed to clean up their places, preparatory to a shutdown of indefinite duration. Statements subsequently made by officials of the company are to the effect that the shutdown is due to inability of the company to secure sufficient market for its product to warrant continued operation of the shaft. Since January 1 the Wabash railroad, who had a contract with No. 7 mine, have transferred a portion of their business to West Virginia and this has had a direct bearing on the local mine. The company's sales department is making strenuous efforts for additional business and it is possible that the shutdown may not be of as long duration as is now feared. The order to close down the mine affects approximately 500 men, some of whom were working full time while others had only part-time employment. All of the cleanup work was completed on Tuesday and the mine has not operated since. Staunton has been running in a lot of hard luck lately so far as its coal mines are concerned and this most recent bit of unfavorable news came unexpectedly and several months earlier than has been the custom in previous years. The No. 15 mine of the Consolidated will continue to operate, working as many days as the volume of business obtainable will justify.

Workmen during the past week have been engaged in sealing the shaft at the

No. 7 mine of the Consolidated Coal Co., which was shut down several weeks ago.

Quite a number of people take the fact that the shaft has been sealed as an

indication that the mine will not operate, or at least that it will be a long

time until it does.

The Star-Times has been advised by representatives of

the company that the sealing of the shaft is by no means to be taken as an

indication that the mine will remain "down" but that the sealing was done for

the double purpose of reducing expenses at the mine during the time the shaft is

idle and also to prevent the danger of fire. It was pointed out that, should

conditions in the coal market improve so as to make operations of the mine

possible, it would be only a matter of a week or 10 days to get the shaft into

condition for operation.

No. 2 mine of the Mt. Olive & Staunton Coal Company is still idle, and during the past few days the mules have been hoisted from the shaft and the fires drawn from under the boilers. We are informed that the men employed at the shaft have decided to "stay at home" until the company adopts a plan of division of work which will meet their approval. So far as we have been able to learn, the officials of the company have indicated that they contemplate no change from the plan that was laid before the members of the local union. The mine stands ready for immediate resumption of operations whenever the men are ready to work, officials have stated, and the company will operate with a sufficient force of men to take care of the present coal sales, which amount to about 1200 tons daily. At the present, with the mine idle, approximately this much coal is being purchased daily to fill orders. The cessation of work at No. 2 mine means quite a bit to the people of this community. In February the payrolls amounted to about $27,000, in March about $28,000, and for the time worked in April about $12,000 will he paid out today. We sincerely hope that some satisfactory way of resuming operations at the mine will he found very soon.

The No. 2 mine of Mt. Olive & Staunton Coal company this morning resumed operations, after a three weeks' period of idleness owing to a disagreement between the members of the Miners' union and the company officials on the matter of dividing the work. The company had proposed a seven-way split for many of the men, but this was turned down. A new arrangement was then worked out whereby the division of work will be more equal, and at the present time the miners will he divided into six groups, working two days and off ten. Top men will be divided into four groups, according to information given us at the mine. This arrangement, we are informed, will be changed as soon as business justifies. The mine has orders for a considerable amount of coal, with prospects of obtaining more. As soon as the orders demand an increase in the tonnage, the groups will be rearranged to give the men more work. The company has purchased two more loading machines which will be installed as soon as they arrive. One of the new machines is a Joy, the same as the four that are now in operation. The other is a Goodman, which is of a different type, but designed to do the same work as the ones now used. When these two are added it will mean the employment of more men each day, thus increasing the number of days that the men will get. Reports from industrial centers throughout the country indicate a decided revival of business, which should naturally mean an increase in the demand for coal. It is hoped that the Mt. Olive & Staunton Coal company, as well as the other operators in this vicinity, will be able to find new markets so that the miners will again be able to earn enough to live decently.

A notice was posted Saturday at Mine No. 15 of the Bell & Zoller Coal &

Mining Company, located west of Mt. Olive at White City, informing the employees

that the mine would be permanently closed, and it is assumed that all machinery

will be removed from the bottom for use elsewhere. It is supposed that the

action was taken by the company because of the high cost of bringing the coal to

the top.

Mine No. 15 employed about 360 men, most of them from Mt. Olive,

White City and Staunton. The mine was sunk about 50 years ago. It had been

operated by the Consolidated Coal Co. of St. Louis until March 1, when the mine,

together with No. 7 mine, near Staunton, and other properties were sold to the

Ziegler Coal Co., and operated by the Bell & Zoller firm. For a while it was

rumored that either No. 7 or No. 15, or perhaps both, would be shut down, but

evidently the company has decided to continue operating No. 7, where the

equipment includes a coal washer, at least for the present.

Naturally the

closing of No. 15 is quite a blow to the economic welfare of this vicinity. It

is hoped, however, that many of the employees may be placed at other mines of

the company, and those who are at the retiring age can draw their pension

allotments.

The coal mining situation all over the country has been hard

hit by the extensive use of oil and gas as fuels, and the closing of No. 15 is

the second shut-down in Macoupin County within the past 2 weeks, as No. 1 of the

Superior Coal Company ceased operation last week (about 10 May 1951).

The following notice was posted at No. 7 mine of the Bell &

Zoller Coal & Mining Company, located northeast of Staunton: "Effective August

31, 1951, Bell & Zoller Coal & Mining Company is permanently abandoning Mine No.

7, Staunton. All employees take notice. Wm. P. Young, president." Mine No. 7 is

one of the oldest shafts in central Illinois and employed over 200 men, most of

them from Staunton. It had been operated by the Consolidated Coal Co. of St.

Louis until March 1, when the mine and other properties were sold to the Ziegler

Coal Co. and operated by the Bell & Zoller firm. Another mine, No. 15, at White

City was closed down in May of this year.

The company claimed increased

production costs forced closing of mine No. 15. It is presumed this will also be

advanced for the closing of No. 7. Naturally the closing of No. 7 is quite a

blow to the economic welfare of this community. It is hoped, however, that many

of the employees may be able to find employment elsewhere, and those who are at

the retiring age can draw their pension allotments. The closing of No. 7 is the

3rd shutdown in Macoupin County within the past several months. No. 1 mine of

the Superior Coal Company ceased operation in May.

An agreement was reached on Thursday of last week between members of Local

Union No. 18, Progressive Mine Workers of America, and a group of men from

Chicago, whereby Mine No. 7 east of Staunton, will again, resume operations

after a 3 months period of idleness. Some 100 men will be employed at the mine,

all members of Local Union No. 18, most of them from Staunton, with a number

from Mt. Olive will operate on a trail basis of about 3 months. ...

29 Nov

1951: Mine now called "Staunton Mine Seven, Inc."

27 Dec 1951: Mine 7 "Trail

Run" Operation Proves Highly Successful.

Mine No. 7, located about 2 miles east of Staunton, ceased operations Friday,

that being the last day, and the fires under the boilers were drawn, and all the

men employed there either have secured other positions, are looking for work, or

are retiring to qualify for pensions.

Just what effect this shutdown will

have on local economic conditions is problematic, but it is easy to arrive at

the conclusion that the large semi-monthly pay days will be keenly felt, at

least for quite a while unless all of the men find other lucrative employment

and continue to reside here. However, it is hoped that the local business and

professional men, property owners, and all others interested will work together

in an effort to secure other means of employment for those who had been on the

No. 7 payroll.

No. 7 mine was sunk about 65 years ago, and with the

exception of a few years has operated continuously, most of that time by the

Consolidated Coal Co. In March of this year the Consolidated properties,

including No. 7 and No. 15, were sold to the Zeigler Coal & Coke Co., and the

mines were operated by the Bell & Zoller Coal & Mining Company. No. 15 was shut

down in May, and at that time it was hoped that the operation of No. 7 would

continue. However, the general slump in the coal business, together with the

high cost of operation, were given as the reasons No. 7 shaft was also closed.

With the 2 mines now shutdown, the Wabash Railroad has discontinued Karnes

station, east of No. 7 mine, where coal trains were assembled for shipment to

various markets.

Notice to All Employees: No.2 Mine of the Mt. Olive & Staunton Coal Company will

suspend operations Thursday, June 27. All employees are hereby requested to

remove all personal effects from the mine property. George Timmerman,

Superintendent.

With the posting of this peremptory notice, the

above-named coal mine, located at Williamson, about 2 miles southeast of

Staunton's city limits, will cease operation, after a period of continuous

operation for 53 years. The notice also means that after today about 280 men

will be without their usual jobs. The suspension, of course, is a matter of

concern to everyone in this community, although such action on the part of the

company has been expected for a year or more. High cost of operation, and a

declining market for coal, is given as the reason for the suspension.

No. 2 mine of the Mt. Olive & Staunton Coal Company was sunk in 1903, when the

digging of the shaft was started. The coal vein was struck in March of 1904,

when actual production started. In those days mining methods were quite

different from the present time--as practically all of the coal was dug by the

pick and shovel method. As the years went on, undercutting machines were put to

work, although all of the coal was still loaded by hand via the shovel method.

At the peak of the mine's productiveness, about 750 men were employed, and the

tonnage averaged from 4500 to 5000 tons per eight-hour day. In more recent

years, the "hogs" or loading machines were installed in the various working

entries, and the machine method took over, with employment figures dropping

steadily until the payroll averaged about 280 men as of this week. The

suspension notice, of course, wipes off practically all of these men, most of

whom have been with the company for a long period of time. The lax market for

coal caused the daily production to fall off considerably, the average in recent

months being from 2500 to 2700 tons per working day. Mining costs, of course,

have risen greatly at the No. 2 shaft, as all of the entries have been worked a

great distance during the years of operation, in many instances the underground

hauling of the mined coal being over five miles from the hoisting shaft.

We have been informed that all of the machinery in the mine will be prepared

against excessive damage by corrosion from dampness. At the present time there

is no indication that the mine may reopen, unless there should be an enormous

upsurge in demand. George Timmerman, the superintendent at the mine, has been

associated with the company almost from the time the shaft was sunk. He started

as a top laborer in 1905, 52 years ago, and through sheer determination

familiarized himself with the methods of operation. Step by step he won

advancement, until his appointment as superintendent in 1942, fifteen years ago.

"Timmie", as he is familiarly known, informs us that Mine No. 2 holds a fine

record for safety, considering the dangerous nature of such work, as then has

never been a major accident at the mine, in which more than one person lost his

life.

Just what effect this suspension will have on the economic welfare

of this community cannot he accurately gauged. There cannot be any doubt that

the loss of income represented by 280 jobs will be severely felt. Many of the

men employed are in the upper-age bracket, and quite a few will he able to

qualify for their social security payments. On the other hand, there are many

who are perhaps too old to qualify for positions in other industry, and not old

enough for retirement. We sincerely hope that all those who need jobs will soon

be able to make satisfactory connections.

Top Row: C. TALKINGTON, Sec., H. BOYD, A. CONDER, J. CARTER, WM. BOYD, Tres., T.

CONLIN, J.E. DAVIS, Mgr.

Top Row: C. TALKINGTON, Sec., H. BOYD, A. CONDER, J. CARTER, WM. BOYD, Tres., T.

CONLIN, J.E. DAVIS, Mgr.

Center Row: J. HERBECK, C. TRAVIS, L. HUFFAKER, J.

MCILLWAIN, Capt., R. EWBANKS, B. RETBURG

Bottom Row: G. PARKER, J. FAIRFUL, A. BROWNING, G. KESSLER, M. MAYERNICK, M TROJACK, A. MCILLWAIN, J. TROJACK

My Father played on this team while employed as a coal miner in the Virden area. It is my understanding that the team was sponsored by one of the mining companies, and most if not all of the players were miners from the area. My Father was Joseph M. Mayernick (listed on picture as M. Mayernick). He played center on the team and was born and raised in Virden. -- Wanda Mayernick Bober

Contributed by Wanda Mayernick Bober